Innovation in engine technology has been a driving force behind the evolution of automotive, industrial, and commercial sectors. As the demand for more efficient, powerful, and environmentally friendly engines continues to rise, manufacturers like Cummins are at the forefront of developing cutting-edge engine parts.

Cummins, a global leader in diesel and alternative fuel engines, has consistently pushed the boundaries of innovation to meet the ever-changing needs of its customers. In this exploration, we delve into the latest advancements in Cummins engine parts, uncovering how these innovations are shaping the future of transportation and industry.

- Turbochargers: Boosting Efficiency and Performance

Turbocharging technology has become synonymous with enhanced engine performance and efficiency. Cummins has been a pioneer in turbocharger development, continually refining its designs to optimize power delivery while minimizing fuel consumption and emissions. The latest Cummins turbochargers feature advanced aerodynamics, precision engineering, and materials innovation to achieve unprecedented levels of performance.

One notable advancement is the Variable Geometry Turbocharger (VGT), which adjusts the turbine geometry based on engine load and speed, providing optimal boost pressure across a wide range of operating conditions. This technology not only enhances engine responsiveness but also improves fuel efficiency by optimizing air-fuel mixture ratios.

Furthermore, Cummins has been investing in electric turbocharger technology, which utilizes an electric motor to drive the compressor wheel independently of exhaust gases. This innovative approach eliminates turbo lag and allows for precise control of boost pressure, resulting in smoother acceleration and improved drivability.

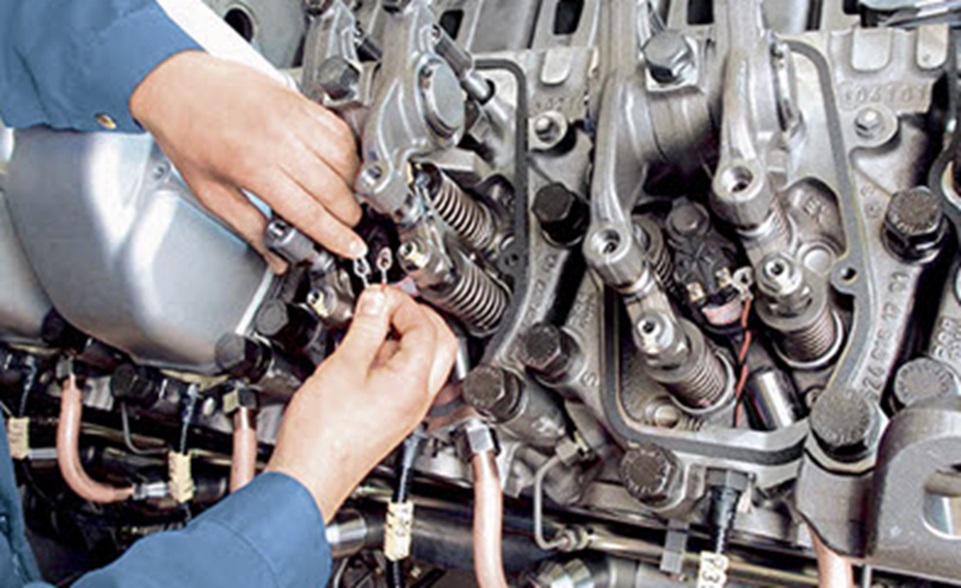

- Fuel Systems: Maximizing Combustion Efficiency

Fuel systems play a critical role in engine performance and emissions control. Cummins has developed advanced fuel injection systems that deliver precise amounts of fuel at high pressure, ensuring optimal combustion efficiency and reduced emissions. One such innovation is the Common Rail Fuel Injection system, which uses a high-pressure rail to supply fuel to individual injectors at precisely timed intervals. This technology allows for finer control over fuel delivery, resulting in smoother engine operation and improved fuel economy.

In addition to conventional diesel fuel systems, Cummins has been investing in alternative fuel technologies, such as natural gas and hydrogen. These alternative fuels offer the potential for lower emissions and reduced dependency on fossil fuels. Cummins’ expertise in fuel system design and integration has enabled the development of engines that can run on a variety of fuels, providing flexibility and sustainability for a wide range of applications.

- Emissions Control: Meeting Stringent Regulations

With increasing environmental concerns, emissions control has become a primary focus for engine manufacturers. Cummins has been at the forefront of developing innovative emissions control technologies to meet stringent regulatory requirements while maintaining engine performance. One such technology is Selective Catalytic Reduction (SCR), which uses a catalyst to convert harmful nitrogen oxides (NOx) into harmless nitrogen and water vapor. SCR systems, integrated with advanced exhaust aftertreatment systems, significantly reduce emissions without compromising engine efficiency.

Cummins has also been exploring alternative methods for emissions reduction, such as Exhaust Gas Recirculation (EGR) and Diesel Particulate Filters (DPF). These technologies work in conjunction with SCR systems to achieve compliance with emissions standards while minimizing the impact on engine performance and fuel economy. Cummins’ comprehensive approach to emissions control ensures that its engines meet the most stringent regulations worldwide, positioning the company as a leader in environmental stewardship.

- Electronic Controls: Enhancing Precision and Reliability

Modern engines rely heavily on electronic control systems to optimize performance, monitor vital parameters, and diagnose issues in real-time. Cummins has developed advanced electronic control modules (ECMs) that utilize sophisticated algorithms and sensor data to precisely manage engine operation. These ECMs continuously adjust fuel injection timing, turbocharger boost pressure, and other parameters to optimize performance and efficiency under varying conditions.

Moreover, Cummins has been investing in predictive maintenance technologies that leverage data analytics and machine learning algorithms to anticipate potential issues before they occur. By analyzing engine performance data in real-time, these systems can detect anomalies, identify potential failures, and recommend proactive maintenance actions, minimizing downtime and maximizing reliability.

- Material Science: Lighter, Stronger, and More Durable Components

Material science plays a crucial role in the development of high-performance engine parts. Cummins has been incorporating advanced materials such as high-strength alloys, ceramics, and composites into its engine components to achieve a balance of strength, durability, and weight savings. Lightweight materials help reduce overall vehicle weight, improving fuel efficiency and performance, while also enhancing durability and longevity.

For example, Cummins has developed advanced piston designs using lightweight materials such as aluminum and titanium, combined with innovative cooling technologies to withstand high temperatures and pressures. Similarly, the use of composite materials in intake manifolds and valve covers helps reduce weight and improve thermal management, resulting in more efficient engine operation.

Conclusion: Driving Innovation Forward

Innovation in engine technology is essential for addressing the challenges of the 21st century, including climate change, urbanization, and sustainability. Cummins’ relentless pursuit of innovation in engine parts has led to significant advancements in performance, efficiency, and emissions control, shaping the future of transportation and industry.

By leveraging cutting-edge technologies such as turbocharging, advanced fuel systems, emissions control, electronic controls, and material science, Cummins continues to push the boundaries of what’s possible, delivering engines that are more dependable, efficient, and clean than before. As the automotive and industrial sectors continue to evolve, Cummins remains committed to driving innovation forward, providing solutions that meet the needs of customers today and tomorrow.